Experiments and Applications

Stan's information about his project

How to measure motor parameters

List of experiments and applications

In my science fair project I conducted many experiments with these electric motors.

In my first year I compared my original reed switch motor to the conventional motor

from a toy car. The results were favorable but they cannot be considered

accurate because these motors were too different: they required different

voltages, contained different amounts and types of wire, the magnets were not

the same, etc.

In the third year of my research I compared several different motors sharing the

same unified mechanical design. The results of this comparison were very

accurate and reliable.

One of the manipulated variables in the experiments was voltage.

The independent variables were the number of magnets on the rotor, the sensor

position, and weights in torque testing.

The dependent variables were the speed, measured in revolutions per minute; and the

relative power, measured as an angle on the torque testing device, or as the

weight, lifted with the help of a speed reducer.

The consumed electric power (in Watts) was calculated as the power supply voltage

(in Volts) multiplied by total current through the circuit (in Amperes).

After building the motors I noticed that the spinning magnets on the rotor could be

used for calculating the speed in revolutions per minute. To assist in finding

the rpm value I used another reed switch. The signals from the second reed

switch were sent to specially built 3-digit electronic decade counter. Last year

I improved this counter replacing the reed switch with a Hall effect switch and

adding an extra decade for easier measurements.

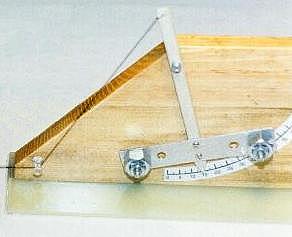

One of the big challenges was the torque measurement. Torque, the twisting force of

a motor, is a very important characteristic. As this task is quite complicated

it was decided to measure a relative power as an angle on a specially designed

device. It is shown on the picture below.

In torque experiments one end of

the string (heavy-duty thread) was taped to the axle, and the other end was

attached to the top of a lever. The bottom end of the lever served as a pointer

showing the angle on the dial. A lath was attached to the pointer end. Several

holes in the lath were used for adding heavy bolts and nuts as weights to

increase the lever resistance.

The spinning rotor of the motor

was winding the string around the axle. The string was long enough to allow the

motor to gain full speed before pulling the lever. The maximum angle was noted.

The actual torque was not

calculated. However, the angle measurements provided very reliable results for

relative power comparison, as the motor with higher torque will turn the lever

to a larger angle.

Last year, for torque measurement, the motor was attached to a

speed reducer. One end of the piece of thread was affixed to the axle of the

speed reducer, while the other end contained a hook, which was holding a box. As

the motor spun, the thread was slowly winding onto an axle. This lifted the box.

The speed reducer ratio was approximately 1:150, which means that the motor

needed to make 150 revolutions to make the axle rotate one turn. The box that

was lifted contained a specific number of weights, which were actually ceramic

tiles. Three ceramic tiles weighed exactly 1 lb. To achieve 0.5 lb. increments,

one tile was split in half. The picture below shows also a regulated power

supply (in the upper right corner) and the electronic counter (on the right

side).

Some of the motors were powerful enough to lift up to 4 kg (9

lbs) on 6V. The speed reducer increased the power of the motors, but decreased

their speed significantly.

Project CD available at the ordering page

contains full information about my experiments including all graphs, tables, etc.

It is very easy to measure electrical parameters of the motors.

This is how you can measure voltage:

This is how you can measure current:

To measure voltage, current and

other electrical parameters you need a multimeter. It should be able to measure

currents up to 2 A or higher. A good digital multimeter is available at our

ordering page.

You can calculate the consumed power of the motor by multiplying current and

voltage.

One of the more difficult tasks is the speed measurement. The electronic counter Stan

used in his project is a complicated device and can be recommended to experienced

users only. The principles of its operation are briefly described in Forrest Mims book on

"Digital Logic Circuits" (see Links section). We added a similar RPM counter

to the list of our products. You may buy a kit and assemble it yourself or order preassembled

ready to use device.

There are some

other suggestions we received from our customers that may be used for the speed

measurement.

Mark Seale suggested to use a strobe light (stroboscope) to determine RPM. Many strobe lights have

active counters showing the flash rate. Brad Higgins used a bicycle counter. Optical tachometers may be used to determine spin rate, however they require a propeller attached to the motor which may slow it down. Frequency may be measured to calculate the speed. Or just attach a string with a small weight

and measure with stop watch the time needed to lift the weight the certain

distance (this method is good only for a relative comparison).

Here is a summary of the experiments you may conduct with these motors:

- Try to compare motors with different principles of operation.

- You may experiment with different electromagnets (different lengths or gauges of wire on the coil). Experimentation kit #2 provides 25 and 29 gauge wires in addition to 27 gauge included with every motor kit.

- Measure and compare different electrical parameters as described earlier.

- If you are building a reed switch motor you may add a speed control unit to it. The speed control unit is included with experimentation kit #1.

- You may design a device to measure the speed in RPM (revolutions per minute) or find any other way to do it.

- Try to find a way to measure the torque – the twisting force of a motor.

- Measure and compare speed and torque on different voltage settings (1.5, 3, 4.5, 6, etc.)

- Experiment how different sensor positions affect motor parameters. You may find that changing position of the reed switch or other sensor can change the direction of rotation.

- Compare the performance of the motor with 2 and 4 magnets on the rotor. With the 2-magnet rotor you may face a "dead spot" problem. ("Dead spot" is a position where the rotor stops and cannot restart without a push).

- If you built a motor with optical control you may experiment with different widths of the disk blades. Trim them with scissors to decrease the width or glue small pieces of opaque material to make them wider.

- You may compare any of the brushless motors shown on our web site to the conventional motor. It could be a simple Beakman's motor - we provide a kit to build one. Or you may choose one of the industrial brushless or conventional motors that we also offer at our ordering page.

Additional experiments:

- If you purchased Kit#8 you may design a circuit with the ability to switch between all 4 different motors.

- Will this electric motor work as a generator?

- How does this motor work under load?

You may

find a lot of useful information on the Project CD (available at the ordering

page) which contains full information about my project.

Possible applications:

- If you attach a small propeller blade to the motor, it may work as a fan.

- You can cut out circles from paper, color them different colors, attach these circles to the rubber plug, and see how these colors mix together. For example, if half of the circle is blue and the other half is yellow the resulting color will be green. You may also draw spirals on these disks.

If you have any ideas for other experiments or applications please

email us – the best

suggestions will be published on this page.

If you do some of the above this

electric motor may not only serve as a model but as a good science fair project.